Unlocking Durability: The Relevance of High Quality Undercarriage Parts in Construction

Unlocking Durability: The Relevance of High Quality Undercarriage Parts in Construction

Blog Article

Make Best Use Of Performance With Resilient Undercarriage Components

In the world of heavy machinery and equipment, the duty of undercarriage parts is extremely important in making sure optimum efficiency and long life. The effectiveness and effectiveness of these components can dramatically affect the general operation of machinery, making the selection of durable undercarriage parts an essential choice for supervisors and drivers alike.

Advantages of Using Sturdy Undercarriage Components

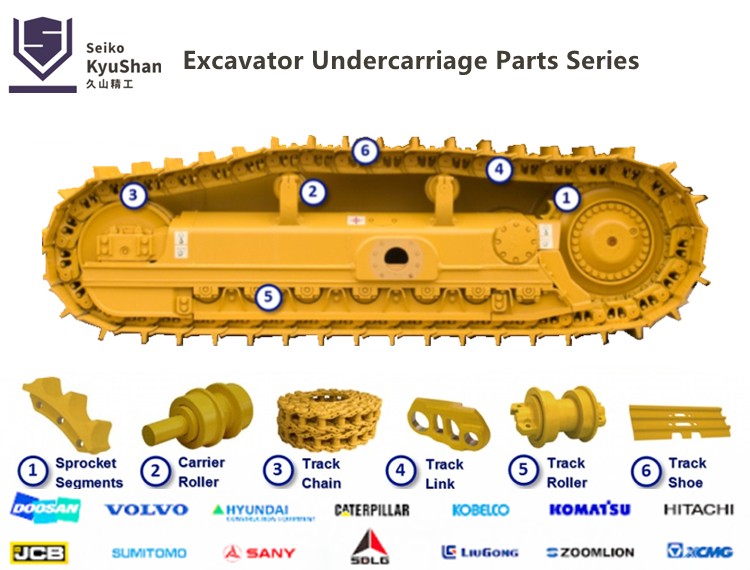

Utilizing long lasting undercarriage components not only boosts the longevity of heavy equipment but also minimizes upkeep prices substantially. By investing in high-quality undercarriage elements, such as tracks, idlers, gears, and rollers, equipment operators can experience increased uptime and enhanced general performance.

Moreover, the longevity of heavy machinery is directly connected to the quality of its undercarriage components. Sturdy parts can hold up against the roughness of requiring applications, ensuring that the equipment stays functional for prolonged durations. As an outcome, drivers can prevent expensive downtime and maintenance costs, inevitably making the most of the roi for their machinery.

Aspects Impacting Undercarriage Sturdiness

The longevity of undercarriage parts in hefty machinery is affected by different important aspects that straight impact performance and long life. Premium materials, such as hardened steel, are necessary for standing up to the extreme conditions and hefty loads that undercarriage parts are subjected to - undercarriage parts.

Furthermore, environmental variables can have a substantial influence on the durability of undercarriage components. Exposure to unpleasant products, extreme temperature levels, and harsh working conditions can speed up deterioration on undercarriage components. Selecting undercarriage parts that are specifically developed to withstand these ecological difficulties is vital for ensuring durability.

Furthermore, the design and engineering of undercarriage parts have a straight impact on their durability. Parts that are designed to distribute tons equally, minimize friction, and minimize tension focus are extra most likely to have a much longer life expectancy - undercarriage parts. By taking into consideration these vital variables, tools operators can make best use of the longevity and efficiency of their undercarriage elements

Maintenance Tips for Prolonging Undercarriage Life

Executing normal maintenance routines is crucial for expanding the life-span of undercarriage components in hefty machinery. To extend the undercarriage life, it is important to often examine for damage. Frequently inspect for absent or loosened screws, harmed rollers, or misaligned tracks, as these concerns can rise my review here and cause more damage otherwise addressed without delay. In addition, make certain that the undercarriage is appropriately oiled according to maker standards to lower rubbing and prevent premature wear.

Another important upkeep pointer is to maintain the undercarriage clean from dust, rocks, and debris. Build-up in the undercarriage can increase wear and rust, causing costly repairs. Cleaning the undercarriage after operation in extreme problems is advised to prevent these issues.

Finally, tracking and recording maintenance activities can help in producing a proactive maintenance schedule. Keeping thorough documents of replacements, fixings, and examinations can offer important understandings right into the undercarriage's condition and performance over time, aiding in anticipating and protecting against possible failings. By following these maintenance ideas faithfully, operators can dramatically enhance the longevity and efficiency of undercarriage components in hefty machinery.

Selecting the Right Undercarriage Parts

Picking appropriate undercarriage parts is critical for taking full advantage of the performance and longevity of heavy equipment. When it involves choosing the appropriate undercarriage elements, there are several variables to take into consideration. One vital factor is understanding the details needs of the maker and the atmosphere in which it will certainly operate. Various applications might ask for various sorts of undercarriage parts, such as tracks, rollers, idlers, and gears. It is important to pick elements that are designed to endure the certain conditions the equipment will come across, whether it be harsh surface, unpleasant materials, or extreme temperatures.

Opting for trusted brand names understood for producing high-performance and resilient undercarriage components can considerably affect the total effectiveness and durability of the machinery. By thoroughly choosing the ideal undercarriage components, devices owners can enhance efficiency, decrease downtime, and extend the lifespan of their heavy machinery.

Case Researches: Boosted Efficiency With Long Lasting Parts

Including sturdy undercarriage parts has shown substantial enhancements in equipment performance. One situation research study entailed a construction business that updated its excavator's undercarriage parts to much more durable alternatives.

In one more instance, a mining procedure replaced the undercarriage parts of its bulldozer with high-grade, resilient alternatives. This switch caused an impressive improvement in the bulldozer's ability to move and overall efficiency. The maker can navigate challenging terrains more successfully, resulting in enhanced operational effectiveness and lowered fuel consumption.

In addition, a logging company invested in durable undercarriage parts for its forestry equipment. The updated elements displayed long term lifespan and increased resistance to abrasion from rough surface. The business experienced reduced maintenance costs and enhanced devices uptime, ultimately improving its lower line. These case studies underscore the concrete advantages of using durable undercarriage parts in optimizing equipment efficiency and longevity.

Verdict

To conclude, utilizing resilient undercarriage parts can significantly enhance efficiency and longevity of hefty great site equipment. Factors such as appropriate maintenance and selecting the right parts play an essential duty in optimizing undercarriage durability. By carrying out these methods, organizations can minimize downtime, boost performance, and ultimately save money on functional expenses. Situation studies have actually revealed that purchasing long lasting undercarriage parts can cause enhanced general efficiency and performance in numerous sectors.

The performance and performance of these elements can dramatically affect the overall procedure of machinery, making the choice of long lasting undercarriage parts a crucial decision for operators and managers alike.Integrating long lasting undercarriage parts has actually demonstrated substantial improvements in equipment efficiency. These instance studies emphasize the tangible benefits of making use of resilient undercarriage parts in maximizing equipment performance and longevity.

In verdict, utilizing resilient undercarriage parts can substantially boost more helpful hints efficiency and longevity of heavy machinery (undercarriage parts). Case research studies have actually revealed that spending in resilient undercarriage parts can lead to improved overall performance and performance in various markets

Report this page